Laying

A new tradition in laying

PIETRAECO is laid in a revolutionary new way: it's simpler, innovation and sustainable. Far lighter than natural stone, PIETRAECO manufactured stone is much easier and quicker to handle, carry and lay. When you choose PIETRAECO manufactured stone, you improve the comfort and energy efficiency of a building, as laying on thermal insulation cuts fuel consumption, making it more environmentally friendly.

Compatible with conventional laying techniques, the PIETRAECO system can be used for both new buildings and when renovating/restructuring existing buildings in order to improve their energy efficiency.

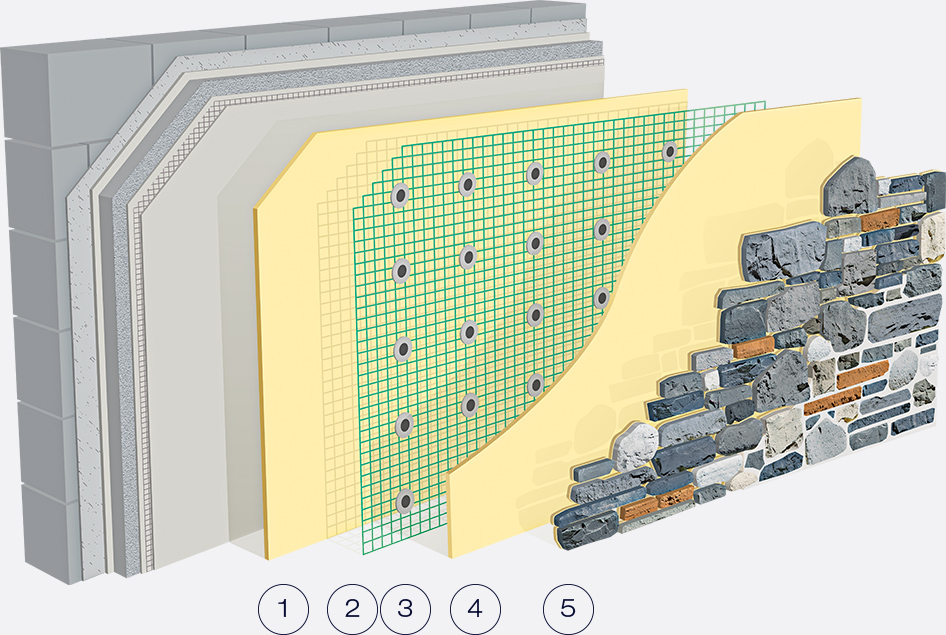

Laying manufactured stone on thermal insulation

- First layer of ECOCOLLA, specific adhesive for PIETRAECO manufactured stone.

- ECORETE, REINFORCEMENT NET (≥ 300 g/m2) drowned in ECOCOLLA skim coat.

- MECHANICAL FIXING with proper plugs, selected to suit type of substrate. Drill the plug holes using an 8mm drill deep into the structure (10 mm above the anchorage) and then clean them thoroughly. Arrange the plugs on the surface in a square mesh measuring 40 cm per side (6.25 plugs/m2). Increase the number of plugs to 12.50 plugs/m2 along the perimeter (2 m from the edge of the building).

- Wait 5-7 days. Apply second layer of ECOCOLLA, specific adhesive for PIETRAECO manufactured stone.

- LAYING OF PIETRAECO MANUFACTURED STONE with double spread technique, according to the instructions given in the Technical Guide, using ECOCOLLA and ECOSTUCCO specific products.

TECHNICAL PARTNERS

Partners par excellence in the field of insulation

PIETRAECO manufactured stone is ideal for thermal insulation, offering many different benefits. PIETRAECO stone guarantees top quality laying for superior EIFS cladding, and so has been chosen by many leading names in the market, such as Weber, Röfix, Mapei, IVAS and Greutol.

These partners offer a wealth of high tech products suitable for use with PIETRAECO stone cladding products, resulting in thermal insulation of exceptional quality when it comes to aesthetics, reliability and sustainability.

TYPES OF JOINTS

As well as the above laying method, proper grouting is essential. The grout colour, joint quality and different techniques used are particularly important and can significantly affect the final look.

ECOSTUCCO expands the possibilities of using grouting to produce a particular finish, thanks to the way it is manufactured. We can produce any type of finish: from ultra smooth, even grouting to far rougher finishes, typical of old natural mortars. Manufacturing times are essential when it comes to choosing surface roughness.

DRY JOINT / RETOUCH

PIETRAECO single manufactured stones are laid next to each other. Grout any open cracks/gaps with ECOSTUCCO.

NORMAL JOINT

Apply a 2-3 cm layer of grout, to suit the stone. Leave the last centimetre empty and then pull the grout across to finish.

FULL JOINT

In this case, the joints are completely filled with grout. The grout is then pulled across with small trowels.

OVER JOINT

Here the joints are completely filled with grout which is then pressed into the joints after 20 minutes using a round profile trowel, with the mortar near and on the surface of the stone.